Equipment & Capabilities

Production Equipment

Mills

- DNM 5700: 51″ x 22″ table with 4th axis capabilities

- (8) Haas VF4: 42” x 22” table with full 5 axis trunnion

- Takumi Seiki V11A: 42” x 22” with 4th axis capabilities

- Haas VF2: 40” x 20” with 4th axis capabilities

- Conventional Bridgeport Mill

Lathes

- (2) HwaCheon Hi-Ecos with 8-10” chucks and up to 12 tooling stations

- (2) Daewoo Pumas with 8-10” chucks and up to 12 tooling stations

- Daewoo Lynx with 8” chuck and 12 tooling stations

- Namseon Conventional Lathe

Capabilities

- AS9100 Certified

- Parts Manufactured per Specification

- Prototype & Production

- Temperature Controlled QC Room

- CNC Turning & Milling

- ERP Quality Management System

- Outstanding Customer Service

- Turnkey Approach

- Deburring Room

Core Competencies

To meet the high-quality standards of our customers and the industries we serve, Vanacore Engineering has the experience and know-how in machining and manufacturing to produce quality precision components that meet or exceed requirements and are delivered on-time. Our planning, production and control departments work closely with one another to maintain strict traceability requirements that are set by each individual customer for their project.

High Quality CNC Machining

Our top priority is to produce high precision CNC machining products under strict quality control guidelines without cutting any corners while, at the same time, having the ability to provide fast turn-around times under the watchful eye of our experienced executives and operators.

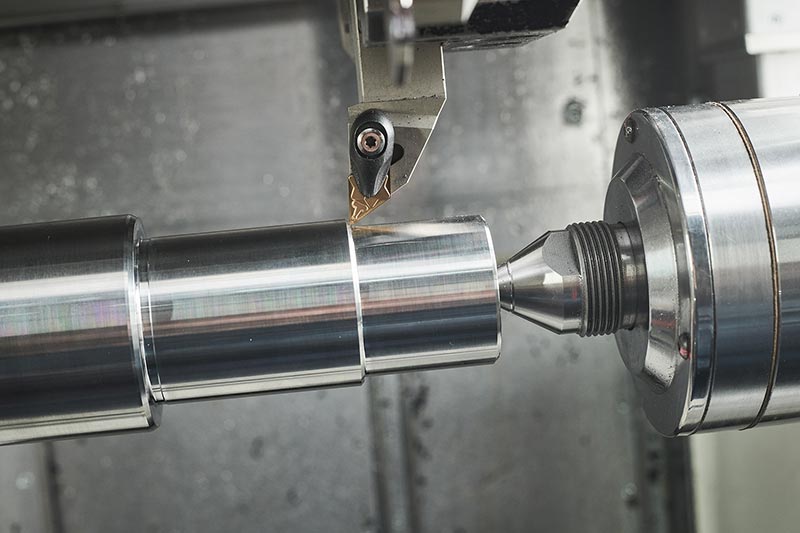

CNC Turning

We have five (5) lathes with up to 10″ chucks that can hold up to twelve (12) tooling stations. Our lathes can turn up to 12 inches and 24 inches long. We can handle all types of metals and plastics and turning operations can hold tolerances of .0002. We also have a conventional lathe for tooling and fixturing purposes.

CNC Milling

We have eleven (11) mills that are 4-Axis and 5-Axis capable. Our highest mill table size is 51” on the X; 20” on the Y; and 25″ on the Z. On our mills, we can hold tolerances of .0002. This is top of the line equipment that allows for a high degree of accuracy and uniformity. We also have a conventional mill for tooling and fixturing purposes.

Turn Key Approach

In addition to providing complete machining and manufacturing services, we can also take care of any or all outside processing needs that you may require. From Heat Treating and Broaching to Anodize and Passivate, we will take care of all your outside processing needs providing you with a finished piece that is ready for its next assembly or final shipment. Our management team will ensure that you receive all the necessary certification and that the processes are done only by our approved suppliers.

Quality Management System

With a strong ERP management system in place that controls in-process quality, your parts will be tracked during each operation and carefully inspected at various stages to ensure it meets the print. First Article Inspection guaranteed for all products and operations to ensure that the manufacturing process is capable of consistently delivering products that meet specifications.

Safety

We are committed to the safety and well-being of our team and all those who visit our facility. Creating a safe environment is one of our top priorities and we continually strive to improve the conditions of our machine shop every chance we get.

A Variety of Metals and Plastics

When it comes to machining, we have used a wide array of high-quality materials, ranging from plastics and aluminums, to inconel and titanium, and everything in between. We track and provide certifications and certificates of conformance for all materials used and routinely administer spot check material testing.

Our commonly used materials include:

- Aluminum

- Stainless Steel

- Copper/Brass

- Titanium

- Inconel/Monel

- Plastics

About Us

Services

Equipment & Capabilities

Quality Control

Let's Get Started

We look forward to hearing about your project & answering your questions. Give us a call